Biotec Lux

Automatic CH boiler

BIOTEC LUX is fully ecological boiler adapted for burning wood pellets. Thanks to application of an advanced controller ST-976 we can control the degree of fuel dosage, automatic ignition as well as fuel extinction. Boiler features Wi-Fi internet module and wireless room regulator ST-292v2 as standard. The construction of boiler exchanger itself is made from attested boiler sheet which guarantees long-lasting problem-free exploitation.

-

Wi-Fi internet module (as standard)

-

Automatic ignition

-

Operation of the mixing valve

-

Automatic cleaning system

-

Attested boiler sheet P265GH with a thickness of 6 mm

-

Dust emission below 20 mg/m3

-

Room regulator (as standard)

-

Controller of 4 pumps and self-cleaning grate

-

Efficiency ~ 90%

-

5-year guarantee for the exchanger tightness, 2 years for smooth running of the boiler

-

Ceramic panels stabilizing combustion process

-

Work in a closed system (option)

BIOTEC LUX is fully ecological boiler adapted for burning wood pellets. Thanks to application of an advanced controller ST-976 we can control the degree of fuel dosage, automatic ignition as well as fuel extinction. Boiler features Wi-Fi internet module and wireless room regulator ST-292v2 as standard.

The construction of boiler exchanger itself is made from attested boiler sheet which guarantees long-lasting problem-free exploitation. A modern and stainless burner with an automatic firing up of fuel and self-cleaning grate was used in the boiler. Cleaning of the heat exchanger is carried out automatically and is controlled with special electronic module which ensures ease of use and a long maintenance-free operation of the boiler. Extended exhaust path together with ceramic elements ensures optimal conditions of firing up of fuel, high efficiency and low pollutants emission which is confirmed by certificates with dust emission below 20 mg/m3.

BIOEC LUX automatic CH boilers parameters

| Rated power | kW | 13 | 18 | 23 |

|---|---|---|---|---|

| Energy efficiency class | A+ | A+ | A+ | |

| Range of heating surface | m2 | do 150 | do 210 | do 250 |

| Power supplye | V/Hz | 230/50 | 230/50 | 230/50 |

| Required exhaust draugh | mbar | 0,15 | 0,15 | 0,15 |

| Min. chimney cross-section / min. height | mm | 160/6 | 160/6 | 180/7 |

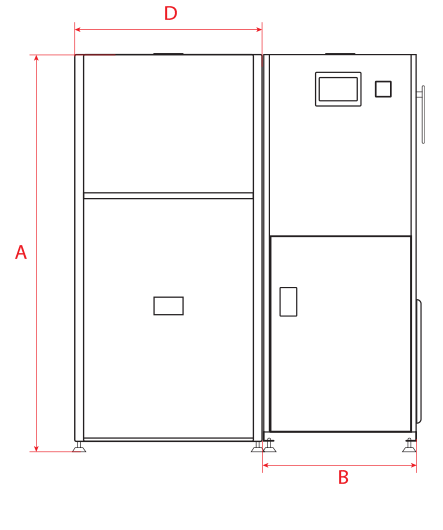

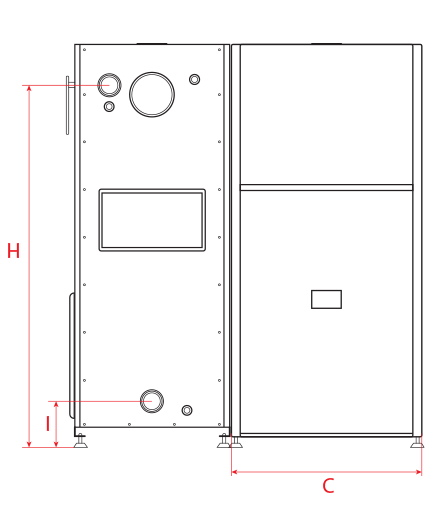

| A – boiler, hopper height | mm | 1350 | 1350 | 1350 |

| B – boiler width | mm | 530 | 550 | 570 |

| C – hopper width | mm | 650 | 650 | 650 |

| D – total width | mm | 1200 | 1220 | 1240 |

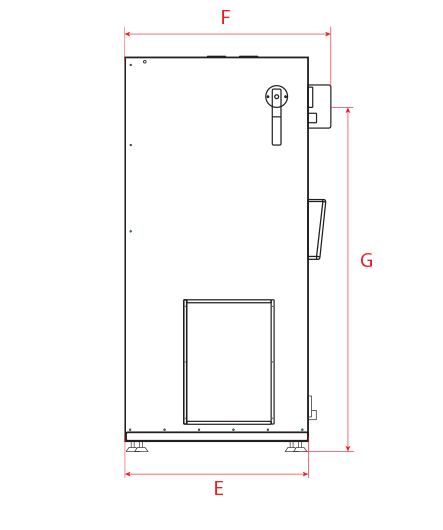

| E – boiler, hopper length | mm | 640 | 640 | 640 |

| F – boiler total length | mm | 720 | 720 | 720 |

| G – height to the middle of the smoke conduit | mm | 1175* | 1175* | 1175* |

| H – height to the middle of the power supply | mm | 1205* | 1205* | 1205* |

| I – height to the middle of the return connector | mm | 120* | 120* | 120* |

| Diameter of supply and return connector | cal | 6/4” | 6/4” | 6/4” |

| Hopper capacity | dm3 | 290 | 290 | 290 |

| Diameter of the smoke conduit | mm | 150 | 150 | 150 |

| Boiler weight | kg | 348 | 372 | 390 |

* A, G, H, I dimensions may be regulated with the help of attached feet, they have adjustment range.

A-I dimensions are provided in millimeters. From +/- 5 mm to 15-40 mm

Find out where to purchase our products

Our network consists of 45 authorized distributors, 365 sales points and installer plants. Find the closest ones and contact us.

FIND YOUR DYSTRYBUTOR