Biotec Eco Mini

Automatyczny kocioł C.O.

BIOTEC ECO MINI jest kotłem automatycznym do spalania biomasy w postaci pelletu o średnicy 6-8 mm. Zaawansowany sterownik pozwala na pełną kontrolę stopnia dozowania paliwa, automatyczne rozpalanie paliwa oraz sterowanie rusztem ruchomym palnika. Konstrukcja wymiennika ciepła wykonana jest z atestowanej stali kotłowej P265GH o gr. 6 mm Kocioł zaprojektowany został z myślą ogrzewaniu budynków mieszkalnych, […]

-

Emisja pyłów poniżej 20 mg/m3

-

Dodatkowa izolacja termiczna

-

Atestowana stal kotłowa P265GH o grubości 6 mm

-

Obsługa zaworu mieszającego

-

5 lat gwarancji na szczelność wymiennika, 2 lata na sprawne działanie kotła

-

Moduł WiFi (opcja)

-

-

-

-

Sterownik 4 pomp i rusztu samoczyszczącego palnika

-

Panele ceramiczne stabilizujące proces spalania

-

Sprawność powyżej 88%

-

Automatyczne rozpalanie

-

Regulator pokojowy (opcja)

BIOTEC ECO MINI jest kotłem automatycznym do spalania biomasy w postaci pelletu o średnicy 6-8 mm. Zaawansowany sterownik pozwala na pełną kontrolę stopnia dozowania paliwa, automatyczne rozpalanie paliwa oraz sterowanie rusztem ruchomym palnika. Konstrukcja wymiennika ciepła wykonana jest z atestowanej stali kotłowej P265GH o gr. 6 mm

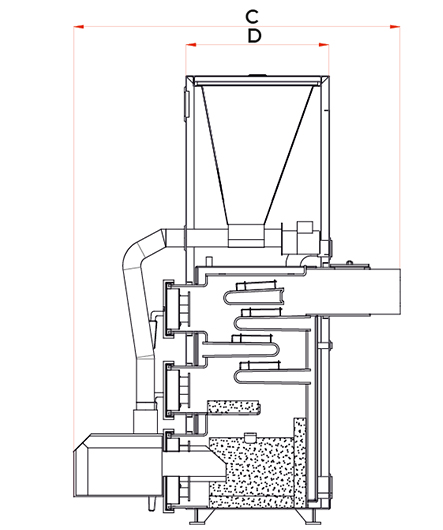

Kocioł zaprojektowany został z myślą ogrzewaniu budynków mieszkalnych, w których wymiary kotłowni nie pozwalają na zainstalowanie kotła automatycznego ze zbiornikiem wolnostojącym lub zainstalowanym z boku kotła. W modelu tym zbiornik paliwa znajduje się nad kotłem tworząc kompaktową, zwartą konstrukcję pozwalającą zmieścić go w naprawdę niewielkich pomieszczeniach.

Parametry automatycznych kotłów C.O. BIOTEC ECO MINI

| Moc nominalna | kW | 8 |

|---|---|---|

| Zakres powierzchni ogrzewanej | m2 | do 100 |

| Klasa efektywności energetycznej | A+ | |

| Max. dopuszczalne cisnienie robocze | bar | układ otwarty – 1,5 układ zamkniety – 2,5 |

| Max. dopuszczalna temp. robocza | oC | 90 |

| Zakres nastawy temperatury | oC | 45-80 |

| Minimalna temp. wody w króccu zasilajacym kocioł | oC | 60 |

| Zasilanie elektryczne | V/Hz | 230V/50Hz 0,5-4A0 |

| Pobór mocy | W | do 100 |

| Wymagany ciąg spalin | mbar | 0,24 |

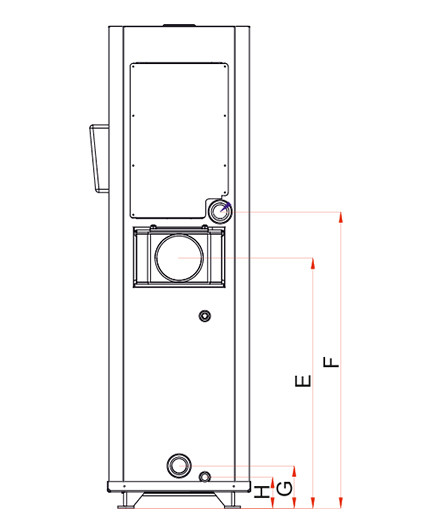

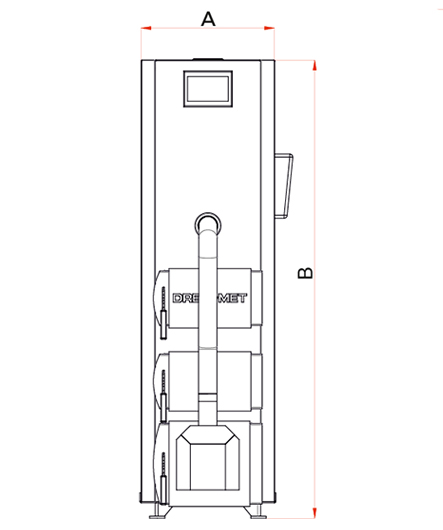

| A – szerokość kotła | mm | 440 |

| B – wysokość kotła | mm | 1500 |

| C – długość całkowita kotła | mm | 1155 |

| D – długość kotła | mm | 480 |

| E – wysokość do środka czopucha | mm | 777 |

| F – wysokość mufy zasilania | mm | 920 |

| G – wysokość mufy powrotu | mm | 96 |

| H – wysokość mufy spustu wody | mm | 195 |

| Pojemność zasobnika | l | 85 |

| Przekrój czopucha | mm | Ø150 |

| Waga kotła | kg | 220 |

Wymiary A-H podane są w milimetrach. +/- 5mm od 15-40mm.

Sprawdź gdzie kupić nasze produkty

Nasza sieć to 45 autoryzowanych dystrybutorówi 365 punktów sprzedaży i zakładów instalatorskich. Znajdź najbliższych i skontaktuj się.

Znajdź dystrybutora